Frequently asked questions

Designing springs

Whether you need a micro spring for the pharmaceutical industry or a more robust spring for heavy industry, we can help, starting from the design phase!

We recommend contacting us early on in the design process. This ensures that the project does not need to be started from scratch due to an ill-fitting or ill-suited spring.

What should you take into consideration in designing springs?

- What is the size of the space where the spring is fitted?

- How much force is required at each point of motion?

- Conditions (temperature and corrosion)

- What type of spring is used (compression, extension, torsion, special design)?

When we have the required information, we design and dimension a spring that meets all your needs. In the design process, we account for purpose of use, materials and cost-efficiency.

Do you manufacture springs to size?

A spring can make or break the entire apparatus, so correct dimensioning is essential.

If our range of standard springs do not meet your needs, you can order a tailor-made spring from us. Made-to-order springs are manufactured precisely to your dimensions, and this may also prove to be highly cost-efficient.

“Our CNC operators have manufactured thousands of different springs. Their model library is certain to include a model applicable to your needs,” says Managing Director Lasse Hahto.

What is not possible in spring manufacturing?

Jousien suunnittelussa on hyvä huomioida ainakin nämä jousien rajoitteet:

- When using CNC automation, bends of the wire parts cannot be too close to each other

- Spring steel cannot be welded

- Spring steel cannot be threaded

What should be taken into account when choosing spring materials?

In planning for the material and the finishing of a spring, you should take the following into account:

- Should the spring be moisture-proof or resistant to other substances?

- Is the spring used in a space with substantial temperature fluctuations?

Our experts provide recommendations on suitable processes based on your spring’s intended purpose of use. All raw materials in our springs come from Europe, guaranteeing materials sustainability and better security of supply.

How is the quality of the springs controlled?

Spring quality control already begins at the production setup phase when the operator checks the dimensions and tolerances specified in the designs. During manufacturing, the operator constantly tracks the process and monitors the progress of the production.

After manufacture, the products are subject to a final inspection by another person.

Each phase of the manufacturing process carefully adheres to the requirements specified in the designs.

More information on various spring types to help with your design

Do you already know which type of a spring you are designing? You can find detailed information below to help you design various spring solutions.

Compression spring

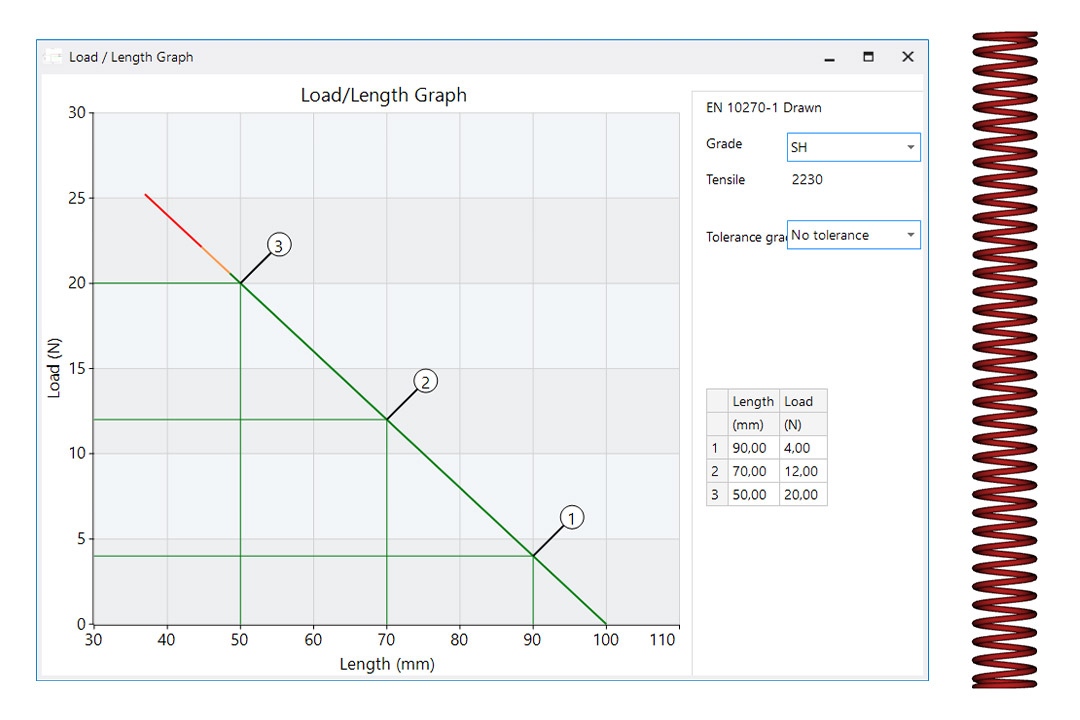

Standard compression springs have a linear spring rate.

The force of the spring is calculated with the formula F = Rs x L, where Rs is the spring constant and L is the amount the spring’s length changes from its equilibrium length.

Example: A 100 mm spring with a spring constant of 0.4 N/mm is compressed to 70 mm: F = 0.4 N/mm x 30 mm = 12 N.

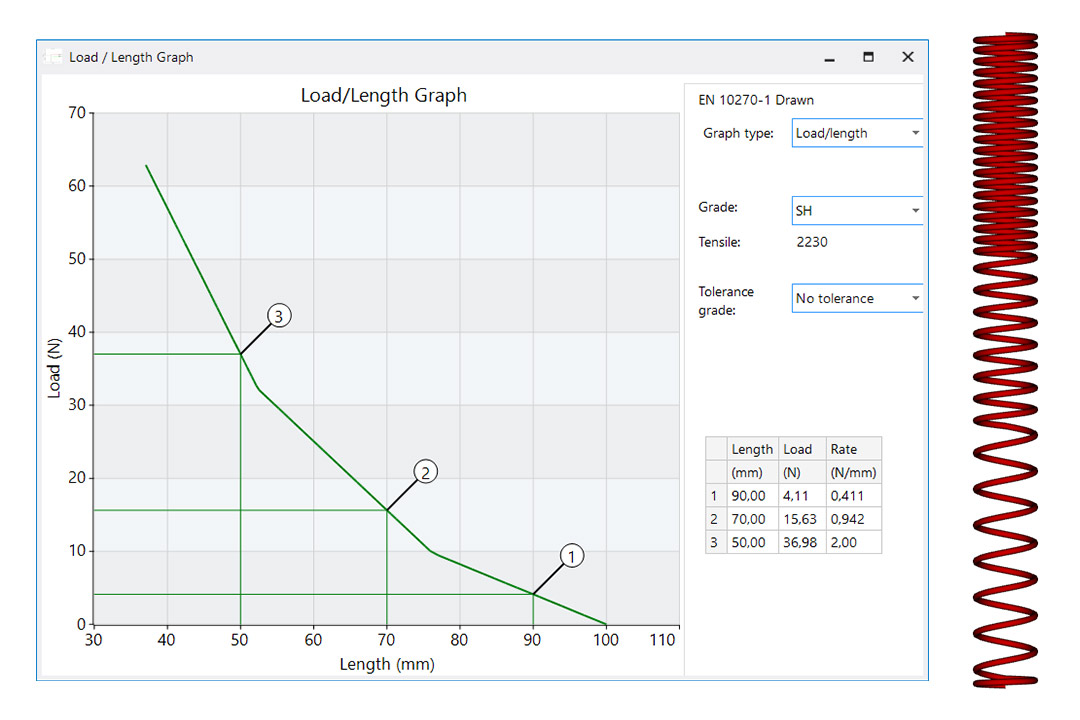

Progressive compression spring

A standard compression spring can be made into a progressive one by altering its pitch, i.e. the gap between the coils, mid-spring. Such a spring features at least two different pitches and an equal number of spring constants. When coils with a smaller pitch are compressed together, the stiffer part of the spring with larger pitches remains the only flexible element.

Shock absorbers in vehicles are a typical application for straight progressive compression springs.

This example spring features three different pitches and three different spring constants, respectively. The length–force graph highlights the three different working positions of the spring.

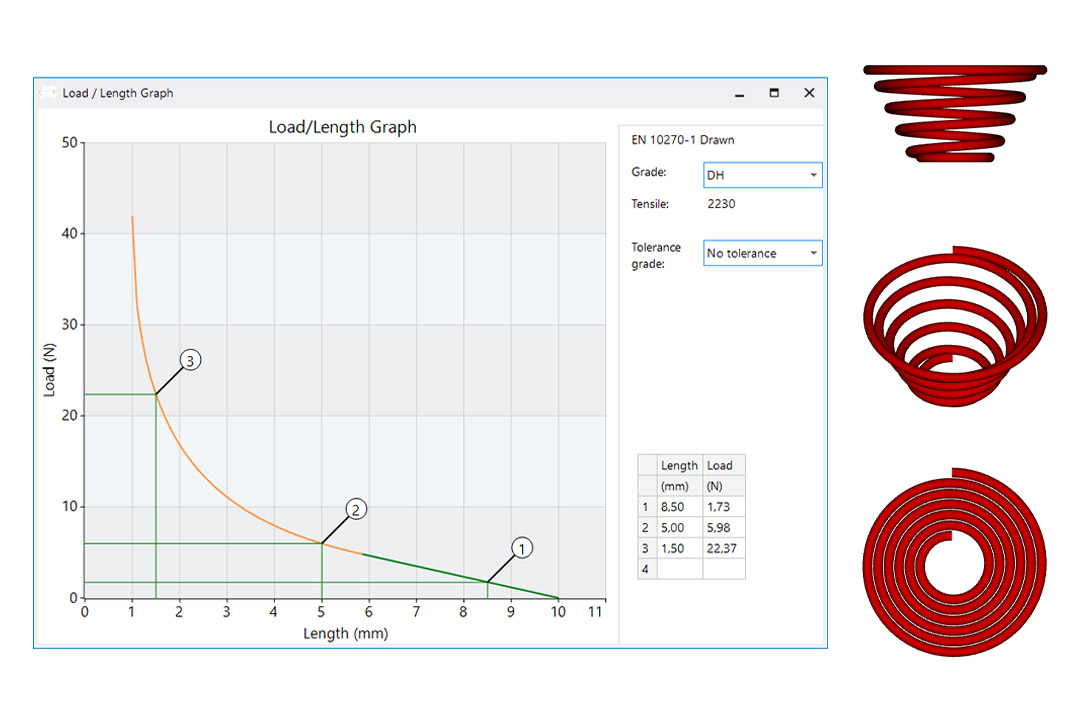

Conical spring

The force of a conical spring increases progressively as the coils compress. The spring constant may be linear at the beginning, but as the larger coils start to come together or are compressed to the same plane, the spring constant begins to increase progressively.

Request a quote

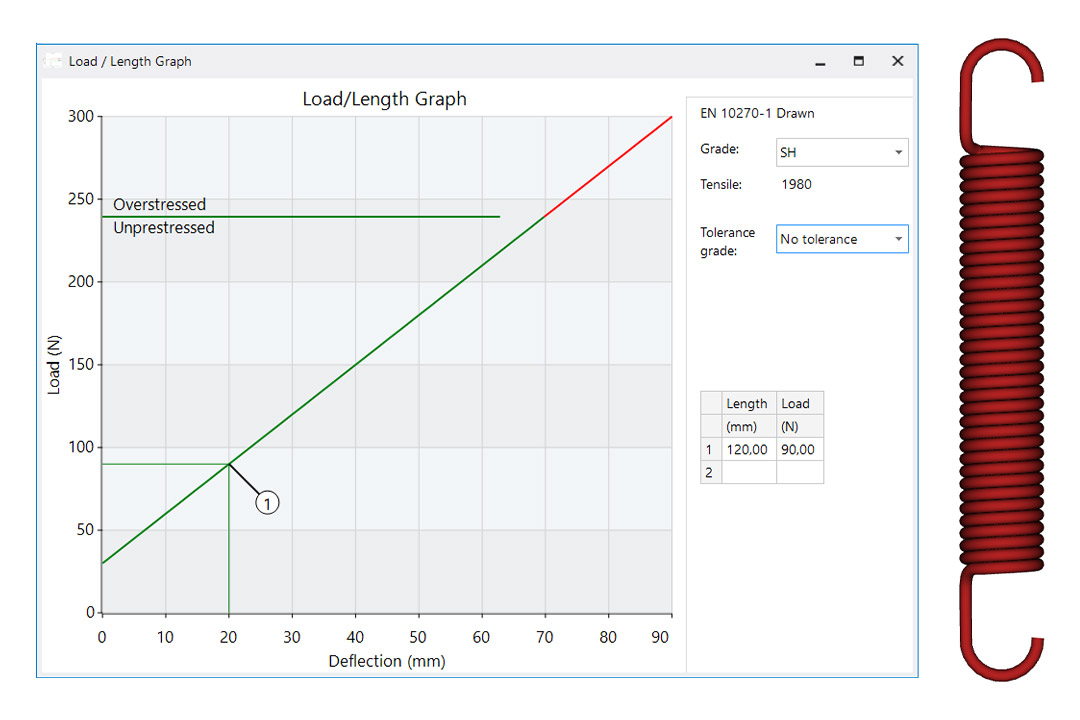

Extension spring

The force of the spring is calculated with the formula

F = F0 + Rs x L, where F0 is the initial tension, Rs is the spring constant and L is the amount the spring’s length changes from its equilibrium length.

Example: A 100 mm spring with an initial tension of 30 N and a spring constant of 3 N/mm is stretched to 120 mm length: F = 30 N + 3 N/mm x 20 mm = 30 N + 60 N = 90 N.

Progressive extension spring

A progressive extension spring is made from a progressive compression spring and U shaped hooks that are passed through the spring. This results in a so-called mooring spring, the operating principle of which is well known to boat owners.

Request a quote

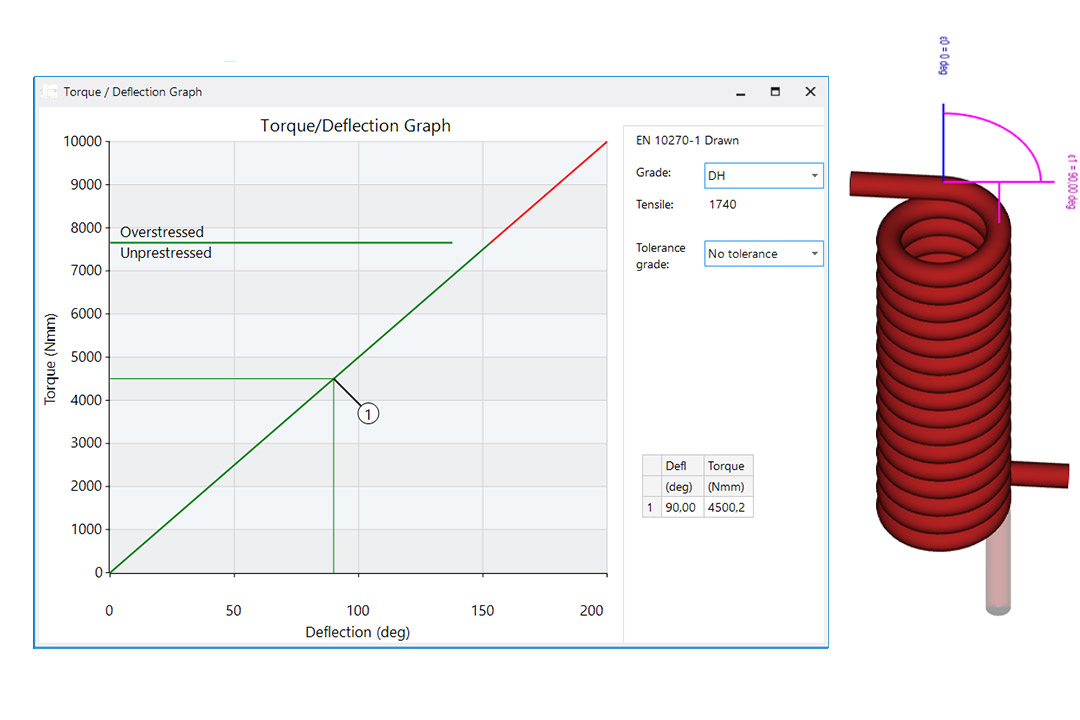

Torsion spring

The strength and torque of a torsion spring depend on its material, the thickness of the material, the diameter of the spring and the number of threads in the spring.

With a double torsion spring, you can pack a lot of force in a small space.

The spring constant of a torsion spring is indicated as torque: Rs = Nmm / degree. To determine the force generated by the spring, you also need the length of the rocker arm and the angle of rotation: F = Rs x a / L, where Rs is the spring constant, a is the angle of rotation and L is the length of the rocker arm.

Example: A door 900 mm wide features a spring hinge with a spring constant of 50 Nmm/°. When the door is opened 90°, the spring generates the following force as the door is pushed from its side:

F = (50 Nmm/° x 90°) / 900 mm = 5 N.

Wire parts

A wire part can serve as a flexible product element, transmit power, affix a piece or work as a switch or an antenna. Wire parts are used, for example, in affixing LED lights due to their low manufacturing costs and great adaptability. Typical products include various custom-made picture hangers and spring pins.

Request a quote